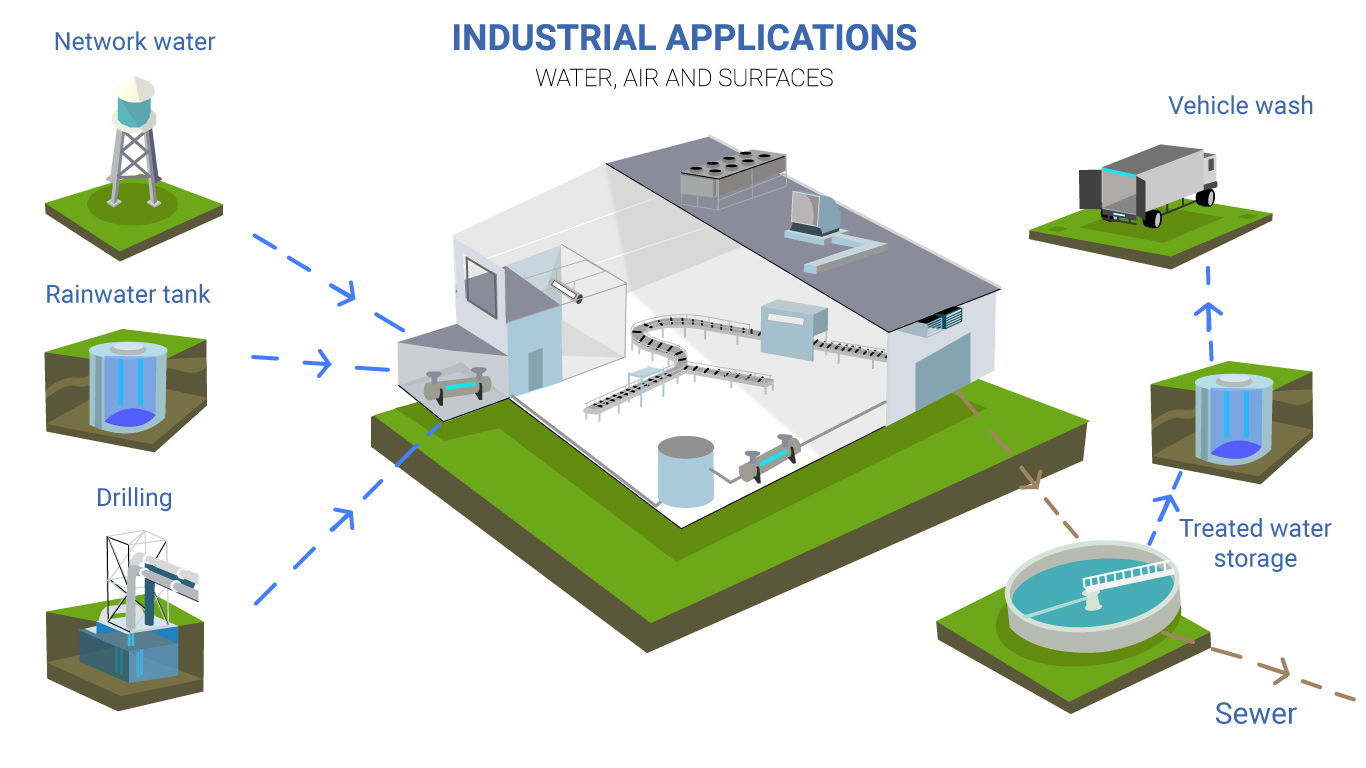

Since 1982, UVRER has been offering water, air and surface treatment solutions adapted to industrial issues. These are clean and reliable technologies, free of chemicals and respectful of the health of users and the environment.

- Industrial water treatment

- Washing water recycling

- Disinfection of conveyors

- Purification of the air in your spaces

We thus offer many ranges of water treatment, air purification and surface disinfection devices (in addition, we frequently produce tailor-made modules, adapted to the specifications of our customers)

Our goal: to enable you to reduce or even completely eliminate the use of chemicals in your business.

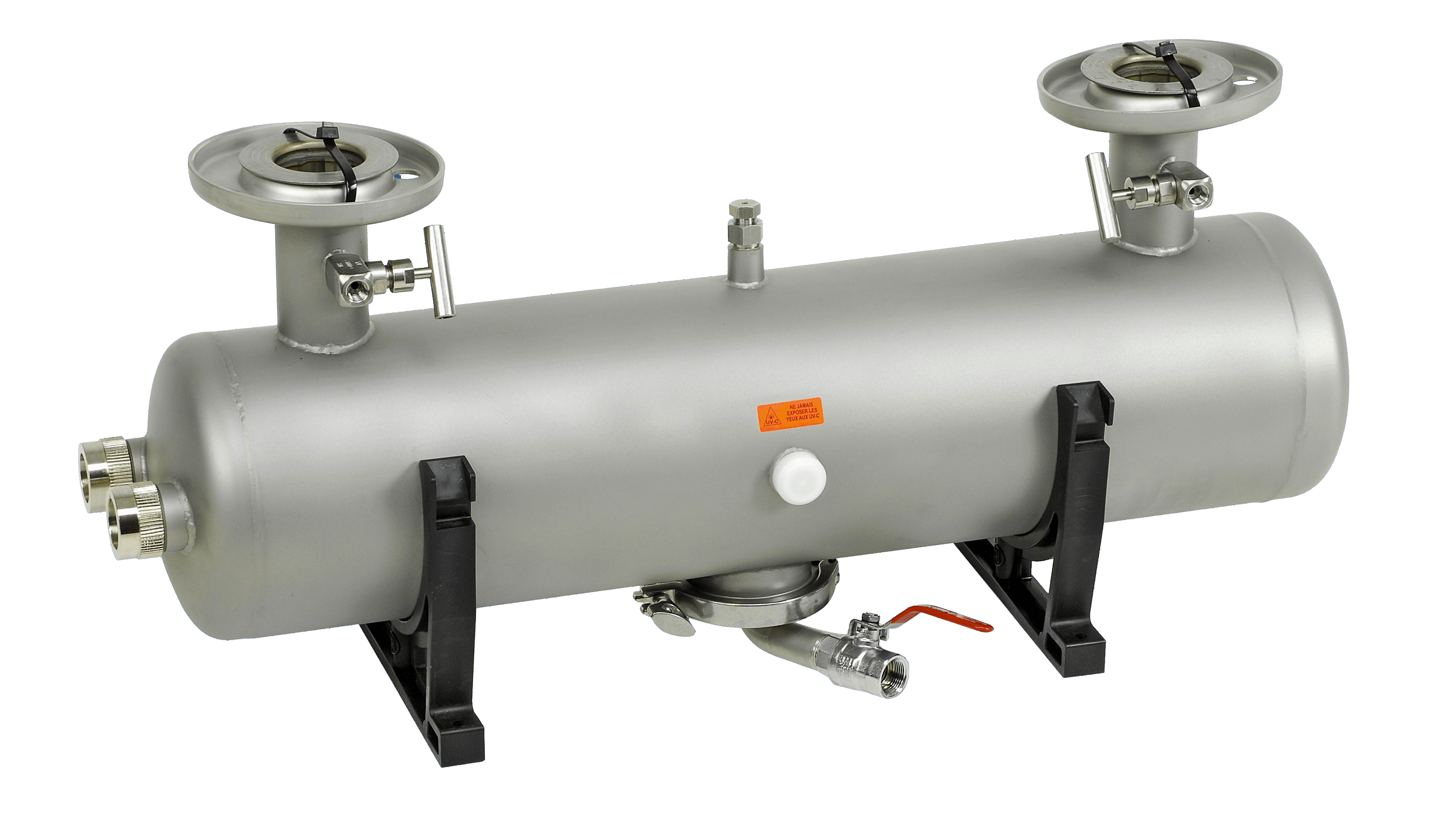

Industrial water treatment

without chemicals

In addition to traditional pre-treatments, our devices make it possible to bacteriologically secure the quality of the fluid before its reuse. Indeed, we intervene at the end of the treatment chain to limit the overconsumption and waste of water. Its bacterial quality is thus maintained throughout recycling. For example, water from a car wash will be reusable for the same application. In the case of treatment at the outlet of the wastewater treatment plant, UVc will make it possible to recycle the water for overhead irrigation.

For this we discuss with you first to know your needs and the quality of your water. Our design office then performs the necessary calculations to identify the most appropriate solution. If our product ranges are not suitable then we offer you a tailor-made solution.

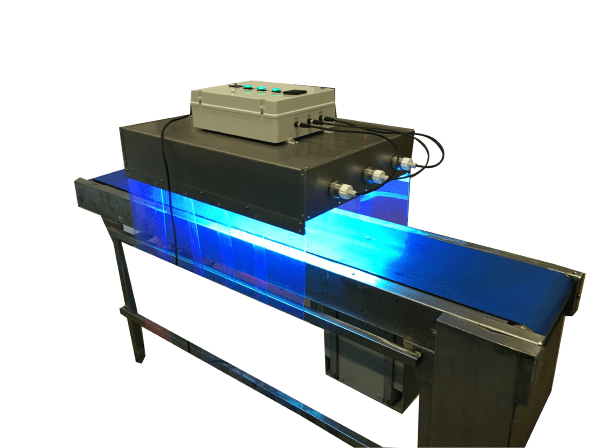

Disinfection of industrial surfaces

without chemicals

The disinfection of surfaces in agrofood and pharmaceuticals is essential in order to comply with hygiene standards: disinfection of conveyors, products or containers and packaging… In this way, you will limit losses due to bacteria and micro-organisms present on food surfaces and you will guarantee the bacteriological safety of your medical products. Ultraviolet rays allow instant disinfection, without adding chemicals.

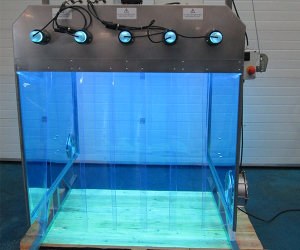

Disinfection conveyors, mobile disinfection tunnel, vibrating conveyors… We produce tailor-made devices that can be easily integrated into a production line. Indeed, we adapt to many constraints such as your production rate, any regulations related to your activity, the efficiency required for the destruction of a specific germ… We calculate, design, manufacture and test everything in-house, in Lyon.

MOBILE DISINFECTION STATION

Disinfection of flower boxes, fruit and vegetable crates… Mobile station, can be integrated above a conveyor or other.

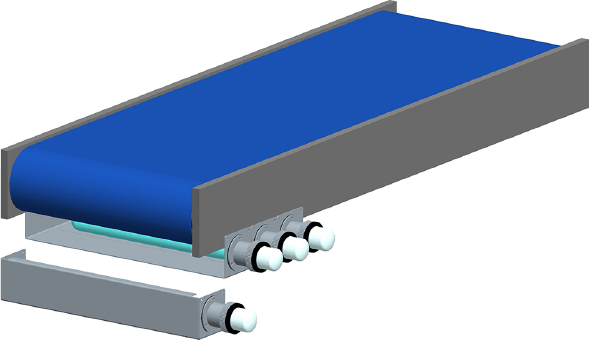

DISINFECTION CONVEYOR

Disinfection of products and conveyor belt.

VIBRATING DISINFECTION TUNNEL

Pouring bin and vibrating conveyor suitable for semolina grains. The vibrations make it possible to turn the beans in order to disinfect all their surfaces.

Industrial air treatment

without chemicals

Before, during and after processing, products are processed, stored and transported. Thus, these steps must be secured to ensure that nothing contaminates the production. For example, fruits and vegetables produce ethylene which accelerates their ripening and in the same way as animal matter, they are victims of airborne contamination. The staff present may also carry micro-organisms that can contaminate the production chain, which is why it is essential to destroy viruses, bacteria, spores and germs to guarantee a stable bacteriological level.

During a study carried out by one of our customers (orange producer), equipping his storage shed with our range of air purifiers enabled him to gain 1 month of conservation (out of 5) and to limit its production losses from 15% to 40%.

BORA VICHY

7 m3/h à 14 m3/h

Single speed, double inner reactor…

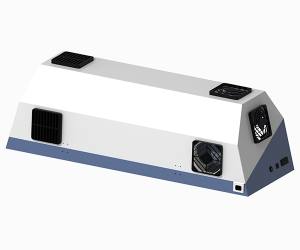

SILUXE 50 & 100

30 m3/h à 100 m3/h

2 speeds, mobile system, hour meter…

HEGOA 500 & 800

500 m3/h à 800 m3/h

Single speed, double inner reactor, hour meter…

English

English Français

Français Español

Español