We know the importance of water quality in the pharmaceutical industry, which has very high demands on this subject. Each production site has its own constraints that the versatility and adaptability of our devices will solve.

At UVRER, we have developed ranges of UV-C sterilizers adapted to the most complex manufacturing and sterilization processes.

Our technology explained

Pharmaceuticals and fine chemicals often require an extremely subtle finish and a very smooth surface. UVRER guarantees devices that meet industry standards.

APPLICATIONS EXAMPLES:

- Sterilization loop

- Process water

- Raw/demineralised/softened water

- Filtration protection

FEATURES:

- Flow : up to 300 m3/h

- 316L stainless steel body

- UV dosage: up to 450 mJ/cm2

- RA 0.8 to 0.6 µm

- Electronic ballasts

- Control cell

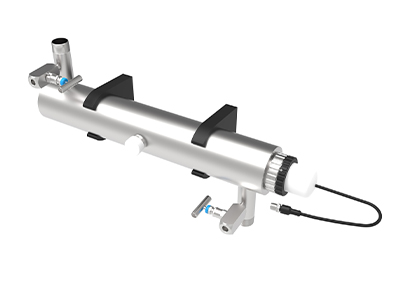

Eureka Industriel range

UV-C sterilizer designed for low and medium flow rates between 1 and 5m3/h

Discover the Eureka Industriel range

Possibility of designing devices with a clamp collar for optimal cleaning and access throughout the interior of the reactor

UV-C technology advantages

- Effective on all types of micro-organisms: bacteria, viruses, yeasts, fungi and protozoa such as Cryptosporidium and Giardia

- Contributes to a better environment (reduction of potentially harmful chemicals)

- UV-C radiation acts instantly without risk of overdose, in one pass

- Adaptation according to the specifications provided

- Ease of installation thanks to modular and compact concepts

- Physical and natural process

- Low operating costs

- Simplified maintenance

- Physico-chemical criteria for stored fluids

- Device can be used without risk in the presence of personnel

English

English Français

Français Español

Español