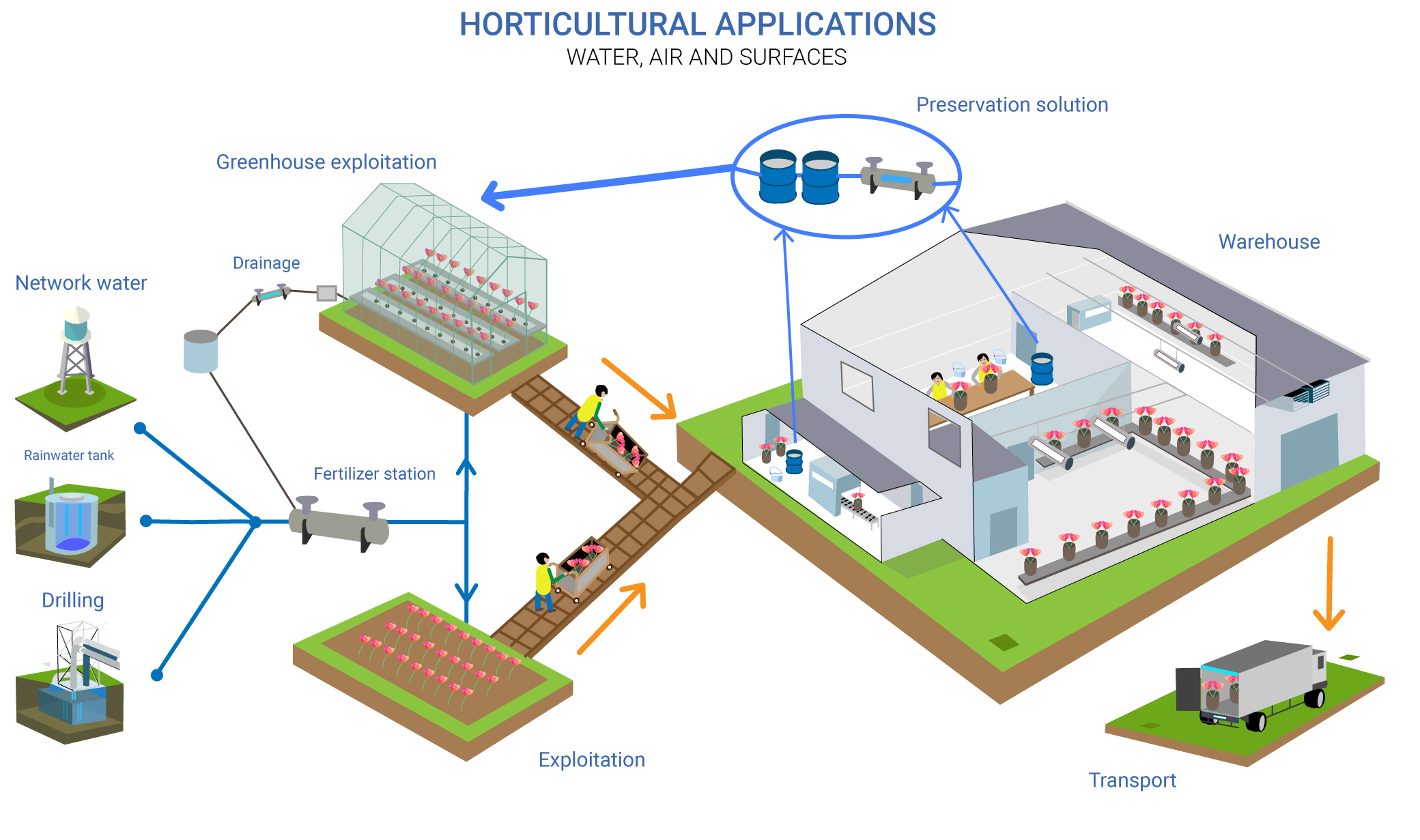

UVRER offers horticultural professionals complete and adapted cleaning solutions to resolve contamination problems in all areas of the production process:

- Recycling and disinfection of nutrient solutions

- Recycling and disinfection of post-harvest solutions

- Elimination of suspended bacteria and fungi in cold rooms

- Disinfection of petals and stems before packaging

Like any fresh product, cut flowers are extremely fragile and perishable. They therefore require specific handling and treatments to ensure optimal presentation and preservation.

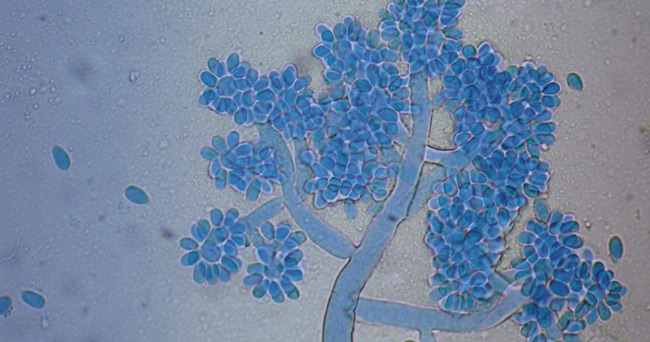

PREVENT BOTRYTIS PROLIFERATION USING UV

In a confined and humid atmosphere, the flowers can develop a mold on the petal, Botrytis Cinerea, which makes them unsuitable for marketing. Flowers can be contaminated by this fungus through air, water or direct contact with other affected flowers.

This micro-organism, which develops even in refrigerated premises (positive cold), is responsible for significant losses, due to poor presentation but also poor preservation. These very easily airborne spores can, through cross-contamination, attack all the flowers on the premises and cause significant financial losses.

TRADITIONAL SOLUTIONS

As a substitute for the necessary treatments by spraying in cultivation or dipping at harvest, one of the common solutions is to treat the air in warehouses using fungicide fumigants, but this is expensive, dangerous for staff and this process leaves deposits on all surfaces. It is also important to note that numerous studies highlight the ability of Botrytis strains to become resistant to the chemical substances usually used.

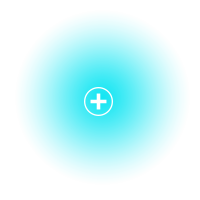

UVDT: THE UVRER SOLUTION

Discover UVDT, an industrial concept of order preparation and processing before packaging allowing the drying and disinfection of flowers before shipment, by directly treating problematic microorganisms at the source, at the surface of the flowers.

Technical advantages

- Trolley disinfection efficiency = 600 stems/min per trolley under UVDT

- Sealing of the cables next to the fans

- Easy height positioning adapted to buckets and stems height

- High powerful fans for drying the stems

- Metal pulleys, lenght increased, strong stability

Characteristics

- Lamp life time: 9 000 hours

- Electrical power: from 570 to 950 W/h

- Supply: 220-230 V AC 50 Hz

WHY CHOOSE UVDT?

- Minimal handling: the UVDT system moves easily and takes up little space. It can therefore be very easily integrated into an existing packaging line

- Speed of treatment: high efficiency in a minimum of time

- More respectful and effective disinfection of flowers. Reduction in the use and handling of disinfection products

- Device perfectly adaptable to an existing conveyor

- Possibility of designing a mobile processing device that can adapt to different specifications

- Sterilization of all surfaces of the treated product

- The combined treatment of the product and its packaging makes it possible to considerably reduce contamination by micro-organisms, which results in a longer shelf life

- All systems are equipped with lamp protection to ensure that no glass debris comes into contact with the products in the event of lamp breakage

- Significant reduction in the use of chemicals

English

English Français

Français Español

Español