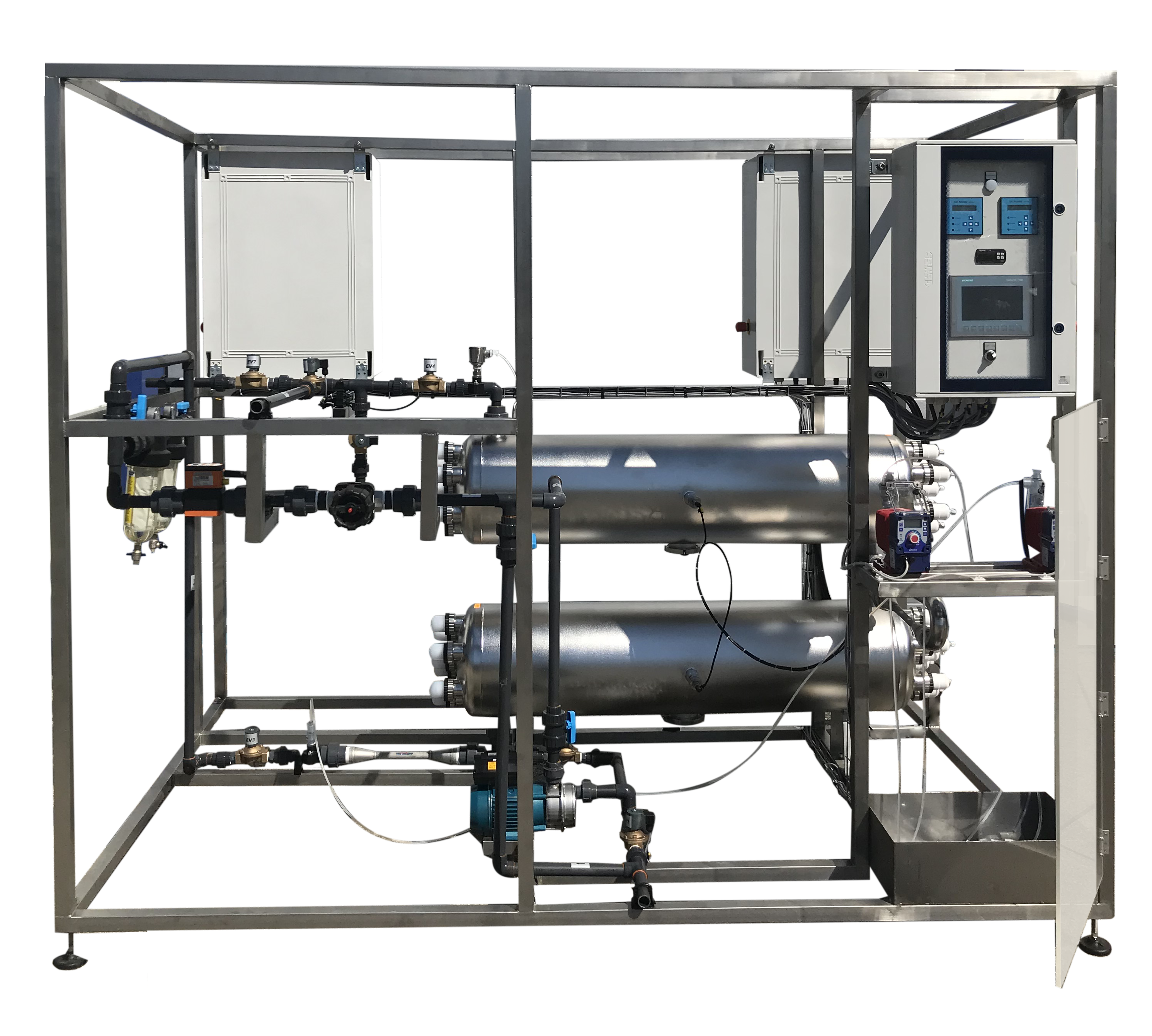

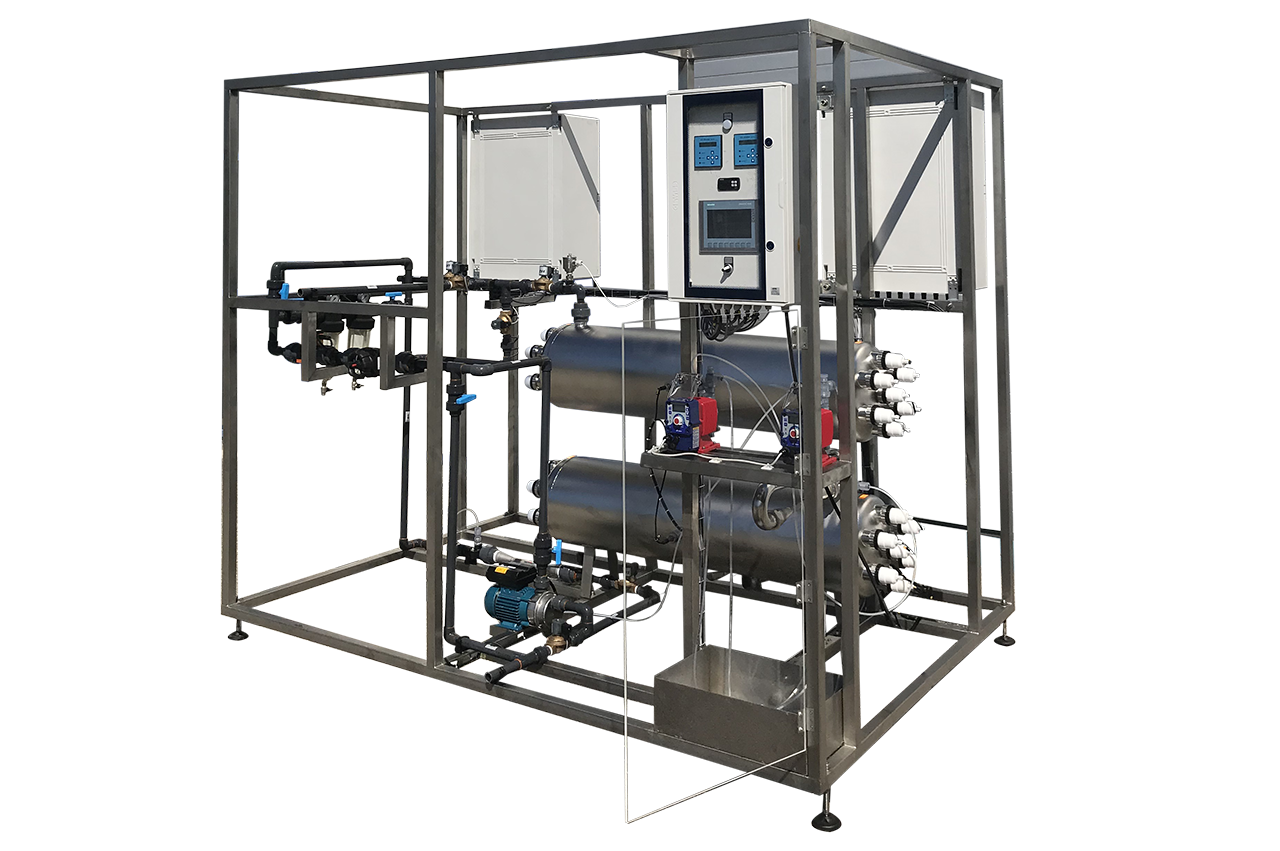

Adapted to chemical industry and answering unresolved issues by conventional methods, we have developed a tailor made semi-industrial pilot.

As part of a collaboration with an industrial chemical company : we have developed, from laboratory to scale 1 pilot, a tailor-made skid for effluent treatment before rejections, based on a combination of UVc and hydrogen peroxide (H2O2). Some explanations : The treatment of wastewater and industrial effluents has become a major challenge for industries. Indeed, the thresholds of rejection keep decreasing while the list of micropollutants to be treated increases.

As part of a collaboration with an industrial chemical key account, we have developed a tailor-made unit for effluent treatment before rejection. Due to the characteristics of the effluent in question (targeted pollutants complexed with other compounds), the previous treatment solutions did not allow effective treatment in terms of cost and / or efficiency.

The purpose of the treatment was to fall below the release thresholds authorized by the competent authorities. To achieve this, we implemented an Advanced Oxidation Method (POA) combining UVc and hydrogen peroxide (H2O2). This combination leads to the formation of hydroxyl radicals then allows the degradation of the polluting molecules.

In a study such as this one, we accompanied our partner from the feasibility phase (both laboratory and semi-industrial pilot) to the scaling of the installation at scale 1.

The tailor-made semi-industrial pilot developed integrates all the elements necessary for the operation of the process on a single skid (UV reactors, injection pump, filtration, control automaton …).

English

English Français

Français