Improve fruits and vegetables post-harvest preservation

The air treatment systems of our ANEMO brand are designed to improve the quality of post-harvest products during storage and thus limit losses, increase shelf life and also limit the use of chemicals during storage.

The main problem during the post-harvest storage of fruits and vegetables is the presence of harmful elements in cold rooms and packaging areas.

Two types of pollution can be distinguished:

- Microorganisms (molds, bacteria, yeasts, etc.): via ventilation or air movements in the cold room, there is an airborne contamination by the micro-organisms present on the rotten fruits towards the healthy fruits.

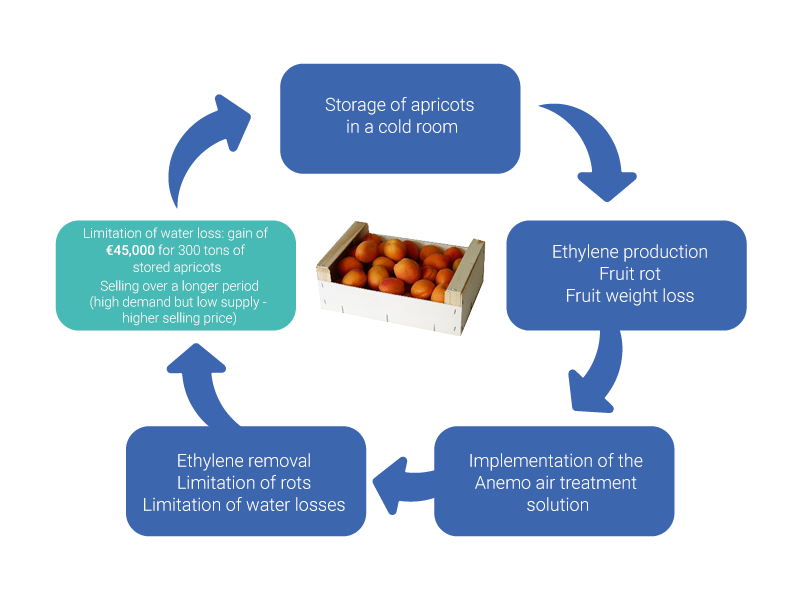

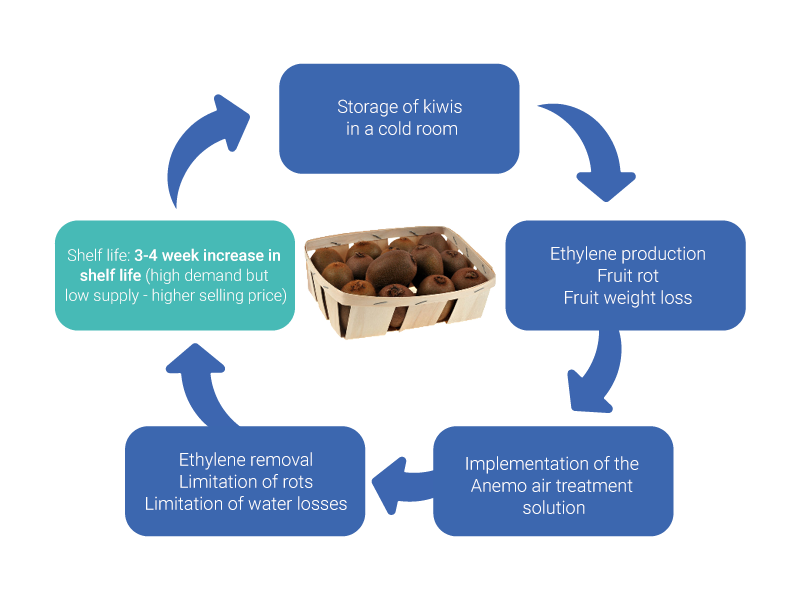

- The presence of ethylene: this gas naturally emitted by the fruits accelerates their ripening. Increased ethylene concentration leads to increased respiration of the fruit (causing a respiratory crisis that stimulates its own formation, resulting in loss of water from the fruit)

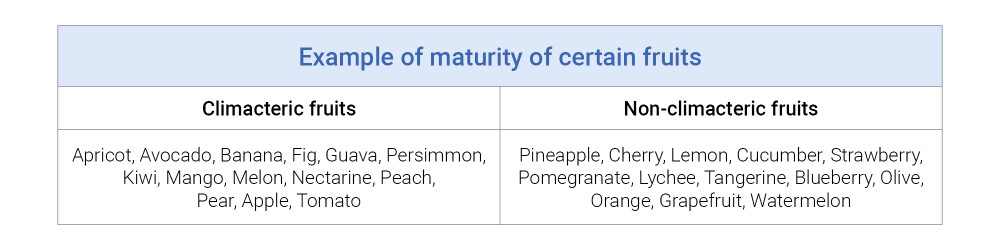

A fruit is said to be climacteric if its maturation depends on ethylene

These two elements, which development is closely linked, degrade the quality of the product, preventing it from being marketed or even consumed.

UVRER Anemo solutions approved for destroying viruses, bacteria and chemical pollutants (VOCs) using Tri-Active technology: Filtration + Photocatalysis + UV-C respond to these two problems with a single air treatment device.

Examples of air treatment in a cold room:

BENEFITS OF ANEMO TECHNOLOGY

- Efficient solutions, fast set-up and easy to use

- Effective against micro-organisms (Monilia, Botrytis, Penicillium…) and ethylene

- Risk-free use in the presence of humans

- Reduced maintenance cost

- Device easily moved from one cold room to another

English

English Français

Français Español

Español