How to adapt to our clients’ needs ? UVrer produces tailormade devices, here are a few examples:

Client : Fruits and vegetables retailer.

Problematic : Reduce the amount of water used when washing and rinsing products.

Lead time : 5 to 6 weeks.

Composition : 1 pump, 2 series of 5 UV, 2 filters, 1 ULF.

Solution : Limit the amount of water used when washing and rinsing products.

– avoid water overconsumption so allowing important saving for client,

– avoid chemical,

– recycle and maintain bacterial for water,

– compact installation: easy to install and connect.

Client : Dairy farmer.

Problem : Make profit by treating catchment water.

Leadtime : 8 weeks.

Composition : water booster, filters, lamp UV, chemical pump, ULF.

Solution : This tailormade module improves the pressure of the water, filters it, and treats it bacteriologically and allows water proper diffusion.

Client : Dairy producer.

Problem : Bacterial protection of a herds watering source.

Lead time : 3 weeks.

Composition : filters, UV.

Solution : This tailormade module treat water against bacteria.

Client : Cheese producer.

Problem : Disinfection of spring water after storage for use in dairy, water and miscellaneous washing.

Lead time : 4 weeks.

Composition : water booster, filters, UV, by-pass.

Solution : This tailormade module has several functions. First it filters and treats water. Secondly, its piping system is intended to redistribute water according to the needs of the farmer (distribution on the farm and filling water tones).

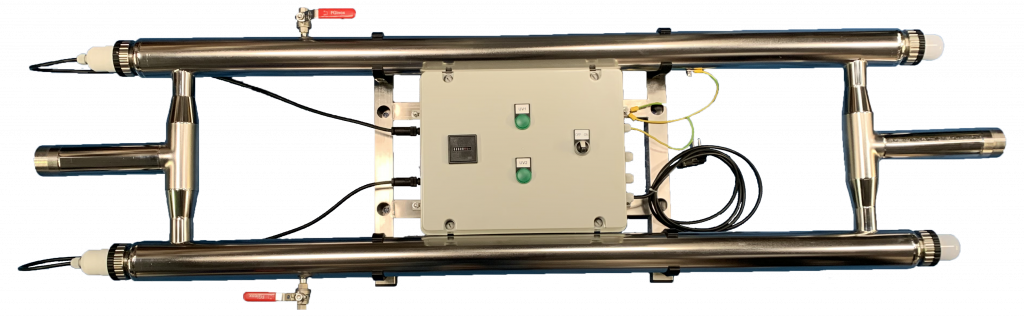

Application : TSA treatment bath chain.

Problem : Algae development.

Lead time : 3 weeks.

Composition : 2 UV in parallel.

Solution : This tailormade module avoid algae in acid tank.

English

English Français

Français